The world’s first Ex-Proof global collaborative painting robot

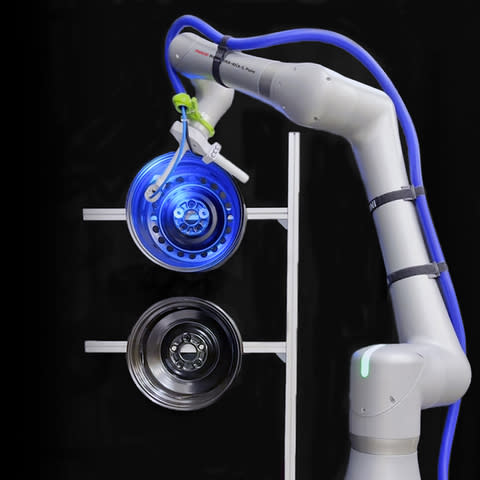

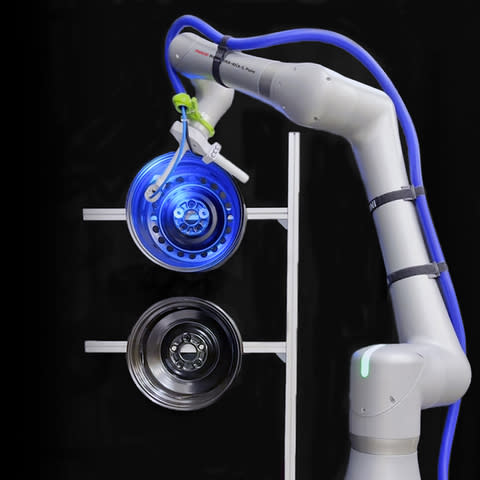

FANUC America introduces the first global explosion-proof paint cobot designed for industrial paint, coating, powder and fiberglass reinforced plastic applications.

ROCHESTER HILLS, Michigan May 6, 2024–(BUSINESS WIRE)–Global Automation Leader FANUC America Unveils New CRX-10IA/L Paint collaborative robot at Automate in Chicago, May 6-9, at booth #1250. As the first explosion-proof collaborative painting robot for use and sale worldwide, the FANUC CRX-10IThe A/L Paint cobot will unlock the benefits of automation for more companies in the fiberglass-reinforced paint, powder coating and/or gel industries. FANUC’s new cobot will not only help power all types of painting operations, including high-mix, low-volume applications, it is also designed to meet the stringent explosion-proof safety standards required in the United States.

FANUC CRX cobots have helped automate more applications, including pick and place, palletizing, machine maintenance and welding, for more companies of all sizes and automation experiences. With the addition of the CRX-10ICollaborative A/L Paint Robot, now even operations without robotics experience can quickly and effectively deploy cobots to automate their painting and coating processes using “easy teach” features including drag-and-drop programming and “lead through teach” “. The benefits of automation include better quality and more consistent finishes, as well as cost and waste savings through accurate and efficient painting.

“FANUC painting robots have been designed and manufactured continuously in Michigan since 1982. Now with the new CRX-10IWith the A/L Paint collaborative robot, more operations will be able to reap the benefits of paint and coatings automation,” says Ed Minch, Director of Automotive Components and General Industry Paint Sales at FANUC America. “We know our customers are struggling to increase your production and efficiency to keep up with increased demand while remaining profitable. Cobots that paint will be a game-changer for companies that may have very little or no prior experience with robots, to help them cost-effectively automate in a short period of time. This is the first collaborative painting robot available for sale and use in North and South America.”

Collaborative robots offer flexible automation with a small footprint and force-sensing technology that allows them to work safely near people. In addition to the standard safety certifications included in the CRX cobot line, the CRX-10IA/L Paint is designed to comply with global explosion-proof safety certifications including IECEx, ATEX, Canada, Japan, Korea, China, Taiwan and Brazil.

The CRX-10IThe A/L Paint cobot has a payload of 10 kg as well as the longest reach in its class at 1,418 mm, allowing the cobot to access large workpieces in even the most difficult locations that can pose ergonomic challenges for humans to reach manually . Featuring the same smooth, rounded design as the CRX series, the CRX-10IThe A/L Paint cobot is lightweight, weighing 45 kg and taking up little space, which can be further improved by stacking the control unit in a lightweight and compact R-30IB Mini Plus Controller. Along with the other CRX cobots, the CRX-10IA/L Paint is maintenance free for 8 years, increasing ownership savings and boosting operations.

As with other CRX models, the CRX-10IThe A/L Paint collaborative robot is easily programmed with the FANUC CRX Tablet Teach Pendant. Through graphic icons, novice users can create paint path programs using the drag and drop interface. Intuitive painting-specific icon commands have also been added for painting applications.

Additionally, the CRX-10IThe A/L Paint cobot has full optimization capabilities with path editing and ROBOGUIDE software. It can be easily integrated with other equipment used in paint, powder, liquid, coating and fiberglass reinforced plastic (FRP CHOP/GEL) applications.

About FANUC America Corporation

FANUC America Corporation, a subsidiary of FANUC CORPORATION in Japan, provides industry-leading CNC systems, robotics and ROBOMACHINEs. FANUC’s innovative technologies and proven expertise help manufacturers in the Americas maximize productivity, reliability and profitability.

FANUC America is headquartered at 3900 W. Hamlin Road, Rochester Hills, MI 48309, and has facilities throughout North and South America. For more information, call: 888-FANUC-US (888-326-8287 ) or visit our website: www.fanucamerica.com. Also, connect with us on YouTube, XFacebook, LinkedIn and Instagram.

View the original version on businesswire.com: https://www.businesswire.com/news/home/20240506160516/en/

Contacts

FANUC America Corporation Public Relations Contact:

Robotics: Cathy Powell

Public Relations and Communications Manager

FANUC America Corporation

Phone: 248-377-7570

E: cathy.powell@fanucamerica.com

Factory Automation: Debra Schug

CNC Strategic Communication Specialist

Phone: 312.818.8876

E: debra.schug@fanucamerica.com