Team develops technology for producing bioplastics from agricultural and food byproducts

× to close

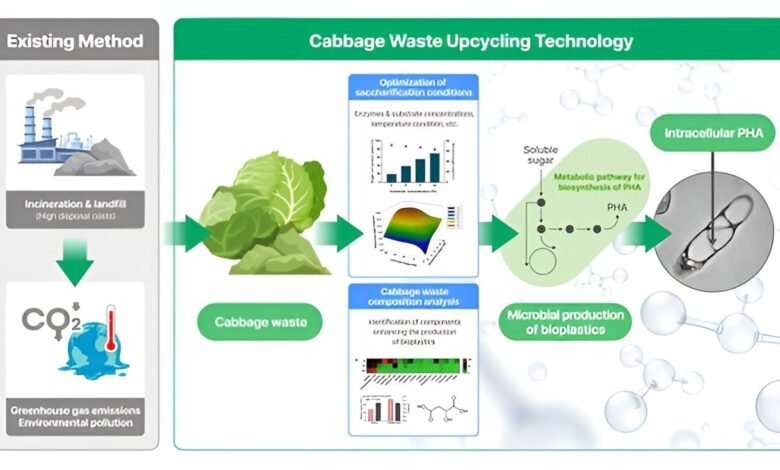

Schematic diagram of cabbage waste recycling technology. Credit: World Kimchi Institute

As kimchi is gaining attention as a global healthy eating trend, cabbage is one of the representative vegetables used as the main ingredient in making kimchi abroad.

The annual global production of cabbage and other Brassica crops is estimated at 72 million tons, and it is estimated that more than 30% of these are discarded during the manufacturing and distribution processes, causing environmental pollution as well as considerable production costs. waste disposal in industry. .

In connection with this problem, Hae Choon Chang, president of the World Kimchi Institute (WiKim), announced that the institute has developed an upcycling technology based on bio-refactoring that can convert cabbage by-products discarded as waste during the food manufacturing process. in biodegradable plastics.

Bio-refactoring refers to a technology for redesigning microorganisms to provide new functions in addition to existing characteristics.

The research team led by Dr. Jung Eun Yang, senior researcher at WiKim’s Fermentation Regulation Technology Research Group, developed microbial strains for the production of biodegradable bioplastics using bio-refactoring technology and identified conditions to achieve a sugar conversion rate of up to 90.4%, optimizing the concentrations of enzymes and substrate used in the saccharification process. The work is published in Journal of Agricultural and Food Chemistry.

In particular, for the first time in the world, the research team discovered that malic acid, one of the bioactive materials in kale by-products, can contribute to improving the productivity of polyhydroxyalkanoate (PHA). PHA is a bio-based biodegradable material obtained by microbial fermentation and is characterized by biodegradability in natural environments.

The newly developed technology can be applied to various agricultural and food by-products, such as cabbage and onion waste used in kimchi production, and is expected to reduce waste by-product disposal costs from the kimchi manufacturing process, which are estimated to at 10 billion won. per annum.

“The results of this research are significant in terms of ensuring an environmentally friendly technology to convert agricultural and food waste into high-value-added materials,” said Dr. Hae Woong Park, director of WiKim’s Technology Innovation Research Division. He added: “We will continue to develop recycling technology in the agricultural and food sectors so that the kimchi industry contributes to achieving carbon neutrality.”

Meanwhile, the research team analyzed the components of cabbage byproducts and systematically categorized several components useful for microbial growth. Based on the research results, the team plans to develop the core technology to convert agricultural and food waste into various high-value-added materials.

More information:

Jung Eun Yang et al, Valorization of Cabbage Waste as Raw Material for Microbial Polyhydroxyalkanoate Production: Optimizing Hydrolysis Conditions and Polyhydroxyalkanoate Production, Journal of Agricultural and Food Chemistry (2024). DOI: 10.1021/acs.jafc.3c07057

Diary information:

Journal of Agricultural and Food Chemistry