Researchers explore raw materials and firing technology for late 6th century Xing kiln porcelain

× to close

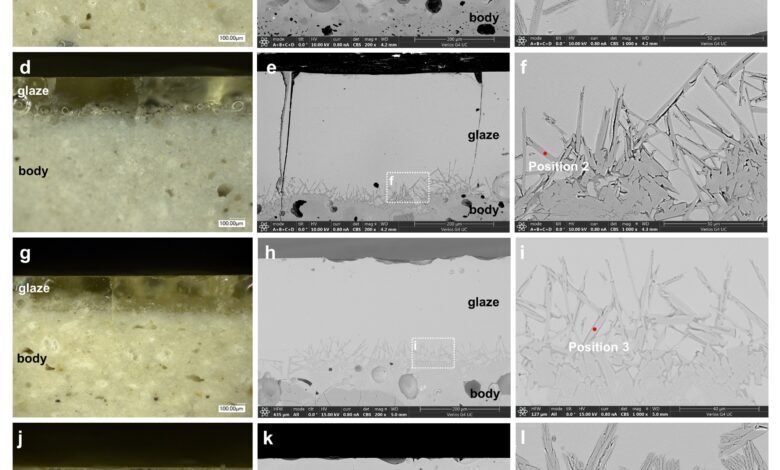

Cross-sectional microstructure of typical samples in early Xing furnace products. Credit: Lu Xiaoke

In the ceramic firing process, the appearance, structure and properties of ceramics are determined by the raw materials and firing technology, so the study of raw materials and firing technology of ancient ceramics has always been a very important topic in archaeological science.

The late 6th century AD was the period when white porcelain was produced and fired in northern China, where the Xing kiln was an important kiln for producing white porcelain. Following archaeological excavations, a large number of kilns in the late Northern Dynasty and early Celadon and white porcelain were discovered, providing important physical data for the study of the origin of white porcelain and porcelain-making technology in northern China.

Researchers led by Lu Xiaoke from the Shanghai Institute of Ceramics of the Chinese Academy of Sciences systematically studied ancient white porcelain and celadon excavated from the Fuwulou kiln in Neiqiu, Xing kiln. Their study, published in Archeometryshed light on the raw materials and firing technology of early porcelain production in the Xing kiln.

In this study, plasma inductively coupled mass spectrometry and thermoelectric ionization mass spectrometry were used to analyze the trace element content and strontium isotope characteristics of raw materials. Researchers found that early Xing ware bodies can be divided into two categories based on trace element pattern, indicating that two types of raw materials were used to make porcelain.

The researchers further discovered that Xing potters deliberately selected a higher quality raw material other than celadon for the production of new wares, antique white porcelain, which generally contains lower levels of trace elements such as V, Cr, Ni, Nb. , Ta, Zr and Hf, which are closely related to zircon and rutile impurities. Analysis of Sr isotope mixing patterns shows that ancient Xing glaze generally did not follow the recipe of mixing wood ash with body clay, but rather mixed with other clays to make glaze.

× to close

Furnaces in the late dynasties of the Northern Xing furnace. Credit: Lu Xiaoke

Furthermore, there are discrepancies in Sr isotopic compositions between antique white porcelain and celadon glaze, suggesting that Xing potters attempted to improve the whiteness by modifying the glazing technology.

The researchers combined thermal expansion instrument, X-ray photoelectron spectroscopy and scanning electron microscope to reveal the differences in terms of firing technology and technical characteristics between celadon and antique white porcelain from the point of view of firing temperature, atmosphere burning and microstructure.

The results show that the Xing porcelains were fired at high temperatures exceeding 1,200℃ and even reaching 1,300℃ with a reducing flame, which is consistent with the characteristics of a wood-fired dome kiln during the late 6th century.

The high firing temperature causes the enamel to become glassy, with some bubbles and residual quartz particles, while the body presents the presence of numerous mullite crystals, according to the researchers.

Among early Xing porcelains, the firing temperature of ancient white porcelain is slightly lower than that of celadon, with average values of 1,242°C and 1,279°C, respectively. This deliberate variation in firing temperature is the result of ingenious technological advances made by ancient potters to reduce glaze build-up and improve the whiteness of products.

The research promotes the emergence of white porcelain in the Xing kiln during the late Sui dynasty, thus establishing a new standard known as “southern blue and northern white” in Chinese history, becoming an important milestone in the history of ceramic development in China.

More information:

Ruofei Zong et al, Firing technology and physicochemical basis for porcelain from the Xing kiln in the late 6th century, Archeometry (2024). DOI: 10.1111/arcm.12969

Diary information:

Archeometry